|

|

MENSCH SEVERE DUTY

The Mensch Severe Duty™ Bar Screen is well known

for its versatility in a wide array of pumping station and

head works projects, along with setting the standard

for robust design in the most severe waste water,

combined sewer, and storm water applications.

You cannot find a more durable screen on the market.

Mensch Bar Screens are custom designed and

fabricated to meet the demands of the environment

in which they are placed. All frame, bar rack, and

drive components are sized according to severe duty

design standards that ensure every screen performs

to the full satisfaction of the client in every application.

There is no comparison in quality and service after

the sale. With over 2000 installations operating in the

United States alone, Vulcan is the leader in severe

duty bar screen applications.

|

|

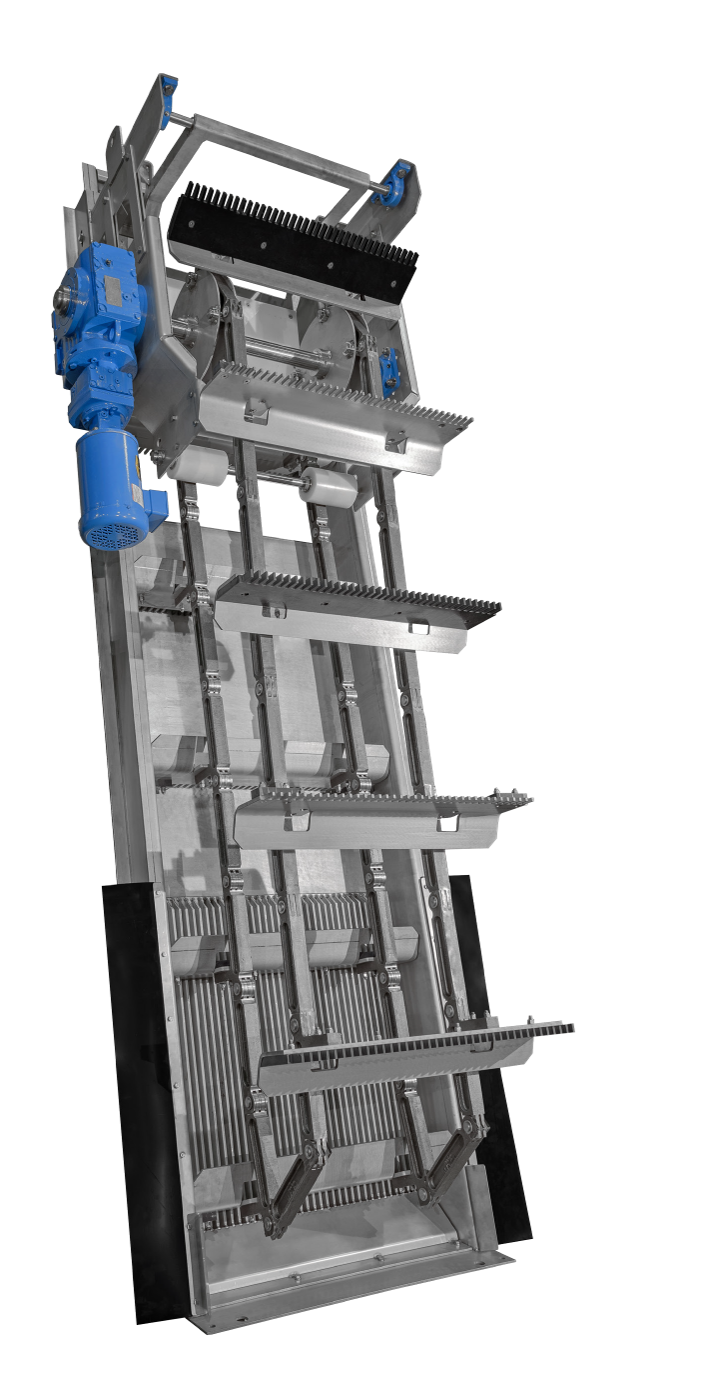

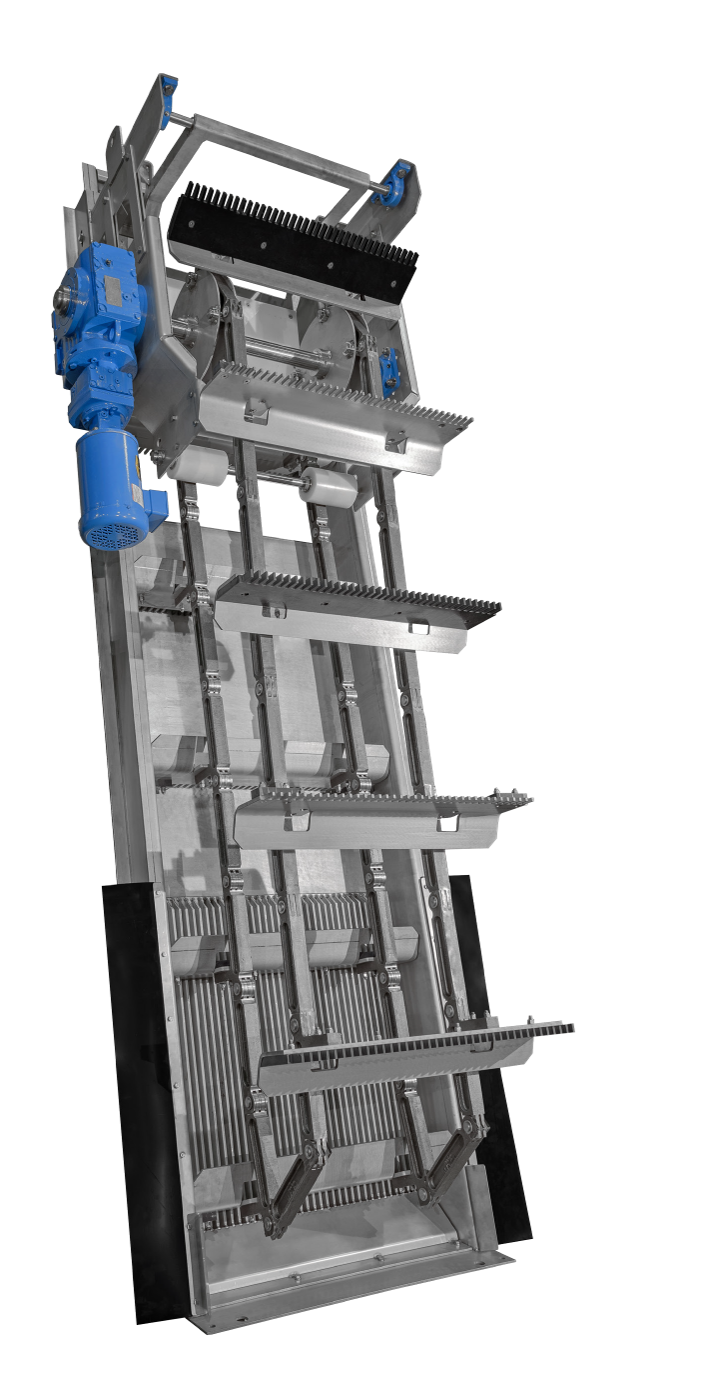

VMR MULTI-RAKE SCREEN

Since 1978, Vulcan has been a leader in manufacturing

quality wastewater equipment. The VMR Multi-Rake

Screen continues this tradition of excellence, incorporating

many of the same features found in our Mensch Severe

Duty™ Bar Screen. Coupling these tried and true features

with Vulcan’s own UL approved fully automatic and

multiple speed controls produces quick and efficient

screenings removal.

Designed for use in high screenings volume applications,

the VMR Multi-Rake Screen can efficiently remove large

amounts of screenings with continuous operation. The

versatility of the VMR Multi-Rake Screen makes it ideal for

special applications of extreme channel depth and severe

screen blinding. Heavy duty components used in the VMR

Multi-Rake Screen ensure a long and productive service

life even under the most severe conditions.

The VMR Multi-Rake screen is an automatic, self-cleaning

mechanical bar screen designed for tough primary and

secondary screening applications.The VMR Multi-Rake Screen can be customized for new

construction as well as existing channels.

|

|

MODEL VKR KNUCKLE-RAKE BAR SCREEN

The VKR Knuckle-Rake Bar Screen is a budget

and maintenance friendly screen intended for many years

of care-free service. The VKR Screen is an automatic,

self-cleaning mechanical bar screen customized for

existing and new construction with bar openings

1/4-inch and larger.So what’s different? The Model VKR Knuckle-Rake Bar

Screen uses a unique knuckle chain link that only bends

in one direction. This allows engagement of the rake teeth

into the bar rack by the knuckle link design forming its

own lower turn-around without a sprocket or guide rail

system in the flow. The knuckle link design allows the

rake heads to disengage from the bar rack should a large

object be encountered or an object is lodged in the bar

rack. However, to ensure an adequate force still exists to

dislodge material in the bar rack, Vulcan placed a high

level of importance on the link design. For this reason,

Vulcan casts the links to weigh 6 pounds; an improvement

of 33 percent over the competition. This is extremely

important for a screen that relies on the weight of the

links and rake heads to maintain rake head engagement

into the bar rack. We want the rake heads to disengage to

remove large material, but we also want to ensure tooth

penetration doesn't suffer when blinding occurs. Each

rake head is provided with rake teeth so that every rake

head engagement cleans the three sides of the bar rack

bars exposed to the screenings. No flat head “staging”

scraper used (or needed).

Rake head shapes control where the screenings end up.

VKR rake heads are formed with a scoop shovel shape

to contain the screenings collected from the bar rack.

That way, screenings are kept on the rake head until the

rake wiper removes them automatically. This reduces the

amount of screenings falling back into the flow or onto the

operating floor.

|

|

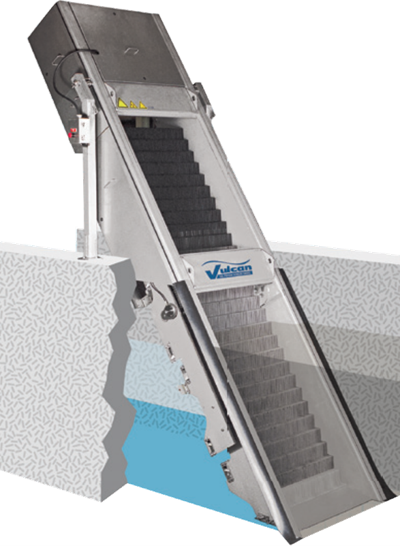

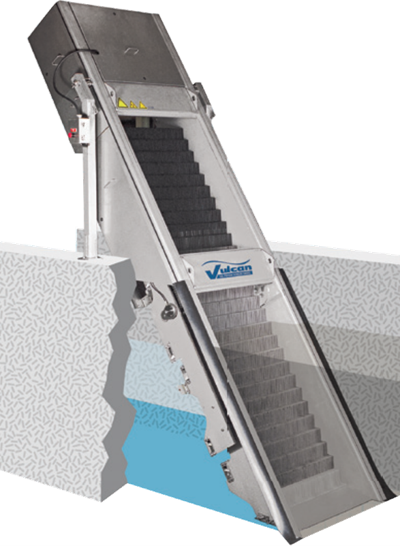

MODEL ESR STAIR SCREEN

The Model ESR Stair Screen is an automatic, self cleaning, fine screen for primary, secondary or sludge

screening in municipal and industrial sewage treatment installations. The screens are also ideal for industrial

applications such as slaughterhouses, tanneries, breweries, and paper plants. The design of the Model ESR

Stair Screen allows for easy installation in new and existing facilities without channel modification. With a

maximum setting angle of 57º, the Model ESR Stair Screen has a compact overall footprint.

The side frames of the Model ESR Stair

Screen are constructed of formed stainless

steel plate having a thickness of 0.24”

(6 mm). The screening elements (aka

lamellas) in the screening area are stainless

steel. The lamellas in the transport area

can be stainless steel or a corrosion

resistant, UV stabilized synthetic material,

depending on the overall height of the

screen. The drive system consists of a

gear reducer, motor, and a dual chain

transmission system with automatic chain

tensioning devices. To prevent corrosion,

ease maintenance and ensure years of

reliable service, the drive system is located

completely above the maximum water

level, and the gear reducer and motor are

encapsulated away from the corrosive

atmosphere of the channel. All moving

parts of the drive system are protected by

removable enclosure panels. The screen

enclosure above the channel are equipped

with removable panels to provide safe

operation and reduce odor.

|

|

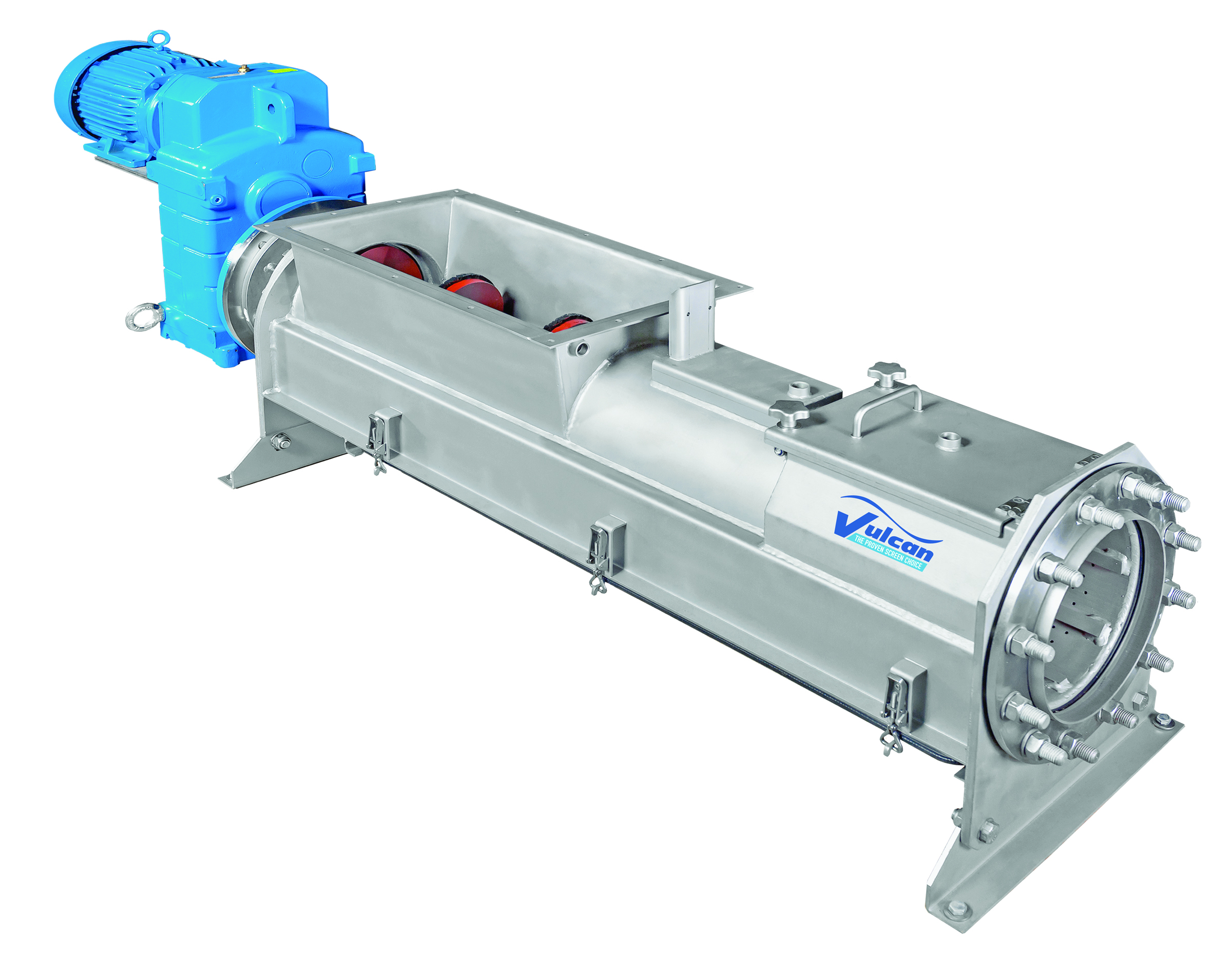

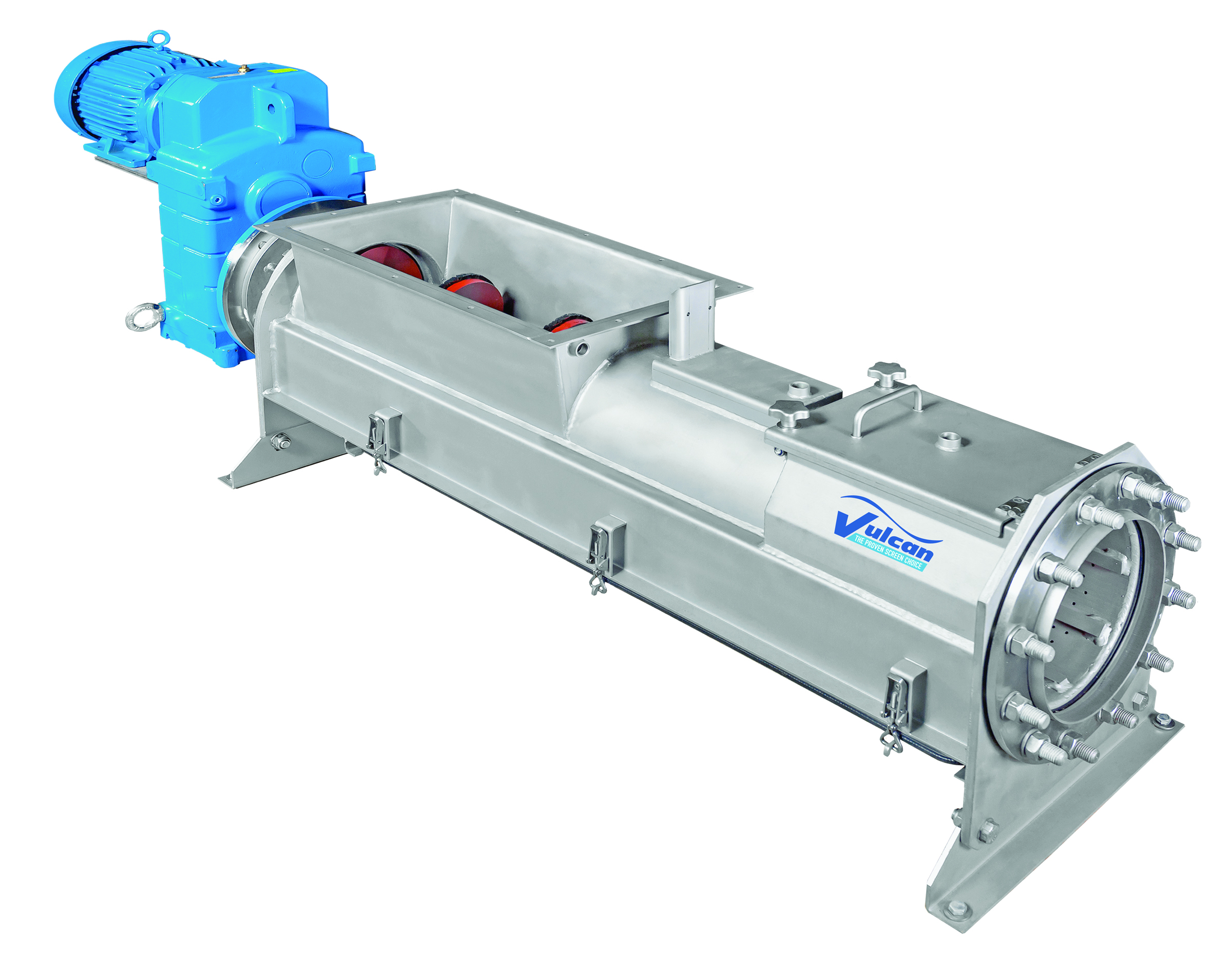

LIQUI-FUGE LFP PERFORATED ROTARY DRUM SCREEN

The Liqui-Fuge LFP, Perforated Drum Screen is an

automatic, self-cleaning fine screen for a variety of

applications from primary to membrane screening in

municipal and industrial sewage treatment applications.

This latest rotary drum screen from Vulcan Industries is

specifically designed for protecting secondary and tertiary

wastewater treatment systems. While other treatment

technologies including MBR, IFAS and MBBR systems are

fouled by hair, fibers and small particles, the fine opening

perforated media of the LFP can effectively remove those

materials in normal operation. The Liqui-Fuge LFP is

designed to accept pumped flow and is internally-fed.

The Liqui-Fuge LFP consists of a drum of perforated media,

internal and external spray system, flow distribution tray,

support structure with trunnion wheels, drain pan (when

required), removable enclosures and a drum drive system.

The drum drive system consists of a gearmotor and a

reliable, smooth running cog belt drive that eliminates chain

maintenance. All wetted parts and the support structure

are constructed of either 304 or 316 stainless steel.

|

|

LIQUI-FUGE LFS WEDGE-WIRE ROTARY DRUM SCREEN

The Model LFS Liqui-Fuge RDS, rotary drum screen

is an automatic, self-cleaning fine screen for primary

screening in municipal and industrial sewage treatment

applications. The screens are also ideal for industrial

applications such as slaughterhouses, tanneries,

breweries and paper plants. The Liqui-Fuge RDS is

designed to accept pumped flow and is internally-fed.

The Liqui-Fuge RDS consists of a wedge-wire drum,

internal and external spray system, flow distribution

tray, support structure with trunnion wheels, drain

pan (when required), removable enclosures and a

drum drive system. The drum drive system consists

of a gearmotor and a reliable, low maintenance

synchronous drive belt. All wetted parts and the

support structure are constructed of either 304 or 316

stainless steel.

|

|

MODEL SS STATO SCREEN

The Model SS Stato Screen is a non-mechanical screening device for separating solids from liquids. Because there are no mechanical parts and the unit requires no power, these screens can be installed with minimal capital investment. With a wide range of uses the Stato Screen is ideal for municipal waste water and industrial applications.

Available in 304 or 316 Stainless Steel with flanged inlet and outlet pipes. Hinged enclosures, extended discharge chutes and spray systems are available as optional features.

|

|

MODEL EWP WASHING PRESS

The Model EWP Washing Press is a spiral press used to wash

organic matter out of screenings material. The Washing Press

washes, dewaters, compacts and transports screenings to a

conveyor, container or other suitable receiving device.

The Washing Press consists of a press body with separate washing

and dewatering sections, hollow shaft spiral, axial thrust bearing

(see photo on left), gear reducer and motor, drain pan, washwater

spray connections and sequencing valves.

The press body is constructed of stainless steel. A wedge wire

drain constructed of individual profile bars is mounted on the

bottom of the press and extends from the inlet hopper through

the washing section. The wedge wire, with 2 mm spacings,

guarantees clog-free drainage of the washwater, while ensuring

screenings capture.

The spiral, of alloy steel construction, is welded to the hollow shaft.

The hollow shaft contains perforations located in the washing zone

to introduce washwater to the screenings from the inside out. A

nylon brush is attached to the trailing edge of the spiral to ensure

debris is thoroughly removed from the drainage area. The drain

pan is constructed of stainless steel, and is located directly under

the press body. A flushing nozzle periodically rinses the drain pan.

Sealed with a gasket, and secured with a latching system, the

drain pan is easily removed for service.

|

|

MODEL ESP SCREW PRESS

The Model ESP Screw Press consists of an

axial thrust bearing with a stainless steel body; inlet

hopper; wedge-wire drain; substantial, precision machined

shafted spiral; press housing with compression zone;

flushing nozzle; press water drain pan and drive assembly.

The shafted spiral is cantilevered off the thrust bearing,

and does not rest in the housing. This eliminates metal-tometal

contact during operation.

The profiled bars used in the construction of the wedgewire

drain allows for greater flow than perforated drains and

helps to prevent blinding. A nylon brush is affixed to the

outside edge of the spiral to aide clearing the drain even

when greasy material is present.

|

|

MODEL TF SHAFTLESS SCREW CONVEYOR

The Model TF Shaftless Screw Conveyor is utilized

for the transport of screenings, grit or sludge in

municipal and industrial wastewater treatment

applications.

The conveyor body can be constructed of 304 or

316 stainless steel. The shaftless screw is available

in high-strength alloy steel or stainless steel. The

screw conveyor utilizes a fully enclosed U-trough with

removable covers. The conveyor body is modular

and custom-built for each application. Multiple inlet

hoppers can be provided to allow solids from multiple

sources to be accepted. UHMW polyethylene liners

are mounted in the bottom of the U-trough and fully

support the shaftless screw along its length.

For screenings applications, a compaction head can

be provided on the discharge end of the conveyor to

dewater and reduce the overall volume of screenings.

A water flushing system is provided as an integral part

of the compaction head to ensure that it remains clear

of debris.

|

|

MODEL ESK GRIT CLASSIFIER

The Model ESK Grit Classifier consists of a stainless steel sedimentation tank fitted with flanged inlet and outlet connections, support legs, baffled sidewall with scum board, integrated U-trough with replaceable non-metallic liner, a shaftless spiral and a gear motor drive. The tank is fitted with covers to fully enclose the process liquid and sediments, and a ball valve is installed at the bottom of the tank for draining. Grit cyclones are also available as an integral part of the classifier. Cyclones allow grit classifiers to receive higher flows.

|

|

MODEL ESW-SRW GRIT WASHER

The Model ESW-SRW Grit Washer is used to wash sediment taken from a grit chamber in a sewage treatment plant. The Grit Washer washes and dewaters the sediment and transports the resultant sand particles to a container or conveyor while the organic matter and wastewater is reintroduced into the flow stream.

The Grit Washer consists of a conical shaped tank with support legs, an internal overflow weir with integral drain pipe, mechanical propeller, discharge conveyor with spiral, gear reducer and motor, washwater headers, air headers and pneumatically operated isolation valves.

The tank, overflow weir and discharge conveyor body are constructed of stainless steel. The spiral is shaftless and is constructed of alloy steel. The drive is mounted on the top of the discharge conveyor and the spiral rests on a replaceable liner inside the conveyor so there is no need for a lower bearing.

|

For more information, please click on the logo below.

|

|

|

.jpg) |

.jpg)